Midea's Robots Enter Factories to Screw: What Challenges Do Humanoid Robots Face in Commercialization?

![]() 04/29 2025

04/29 2025

![]() 503

503

Why do humans have a penchant for "humanoid" robots?

As a child watching 'WALL-E', I yearned for my own 'WALL-E'. That way,

I could delegate cleaning chores to the robot, ensuring impeccable results and freeing up my time

for outdoor play. Children, after all, are inherently playful and inclined towards laziness.

Image Source: Movie 'WALL-E'

However, I never anticipated this scenario becoming a reality so swiftly.

Midea Transforms Robots into 'Workers' in Factories

According to Jiemian News, Midea's self-developed humanoid robots will enter washing machine factories in May, tasked with relatively straightforward duties such as machine maintenance, equipment inspection, and cargo handling.

Midea executives also asserted, "In laboratory tests, humanoid robots' screwing efficiency is already on par with that of ordinary workers."

Furthermore, Midea anticipates deploying humanoid robots in offline stores in the second half of the year, primarily for scenarios like commercial tours and coffee brewing.

Image Source: Shunde Release

In other words, store sales assistants might be the first profession to be replaced by robots?

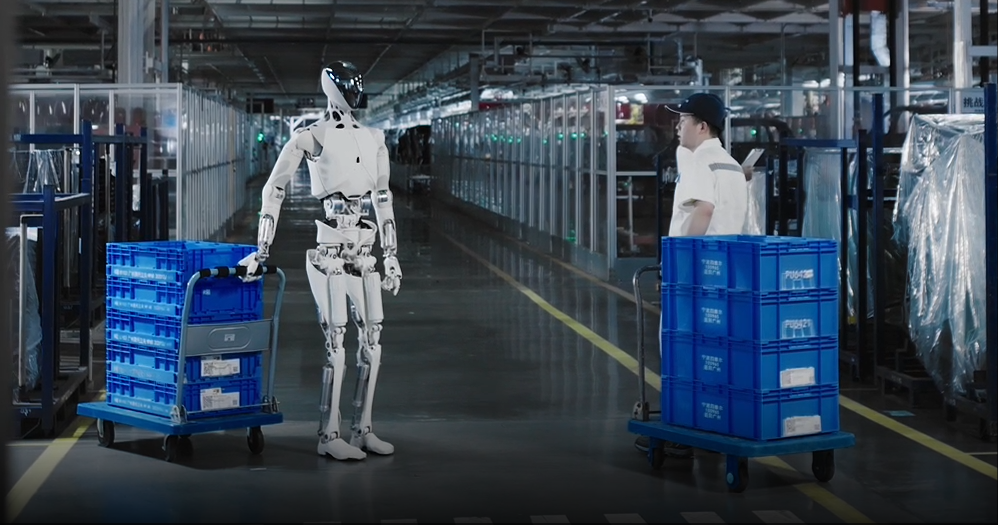

Nevertheless, a quick online search revealed that robots entering factories in 2025 are not newsworthy. Xpeng's humanoid robots have already been operational in their Guangzhou factory, suggesting that the screws on your Xpeng car might have been tightened by a robot.

Image Source: Xpeng Motors Official Website

In fact, it's not just Xpeng; many automakers have ventured into humanoid robot manufacturing. Companies like Xiaomi, Tesla, BYD, and others have already embarked on a race in this domain.

From a product standpoint, automakers and humanoid robots are remarkably compatible.

Firstly, automakers have the advantage of a supply chain for automotive parts. Many key components required by humanoid robots overlap with those of new energy vehicles. Additionally, the automotive industry has extensive experience with precision machining equipment. This can help spread out the production costs of robot components, enable mass production based on market feedback, and accelerate the updating and iteration of robot components. As long as there is progress in research and development, it can be swiftly produced and put into experimental testing.

Image Source: Deep Blue Automobile

Moreover, automakers possess their own factories where they can deploy and utilize produced humanoid robots, assigning them tasks like box carrying and storage sorting. This also facilitates testing of humanoid robots, identifying issues, and making continuous improvements.

Thus, for entities like Midea, Xpeng, and Tesla that control supply chains, building robots is a logical extension of their businesses.

What is the Allure of Humanoid Robots?

Why are humans so relentless in developing humanoid robots?

The first reason lies in their higher flexibility and adaptability. The defining characteristic of humanoid robots is their ability to mimic human movements, enabling them to perform tasks that humans desire but cannot due to various environmental or individual constraints, such as box carrying and sorting in factories, combining flexibility and adaptability.

Previously created dog-like robots were too tool-oriented and limited in their application scenarios due to their size; but humanoid robots are different, offering a broader range of coverage and more diverse scenarios and uses.

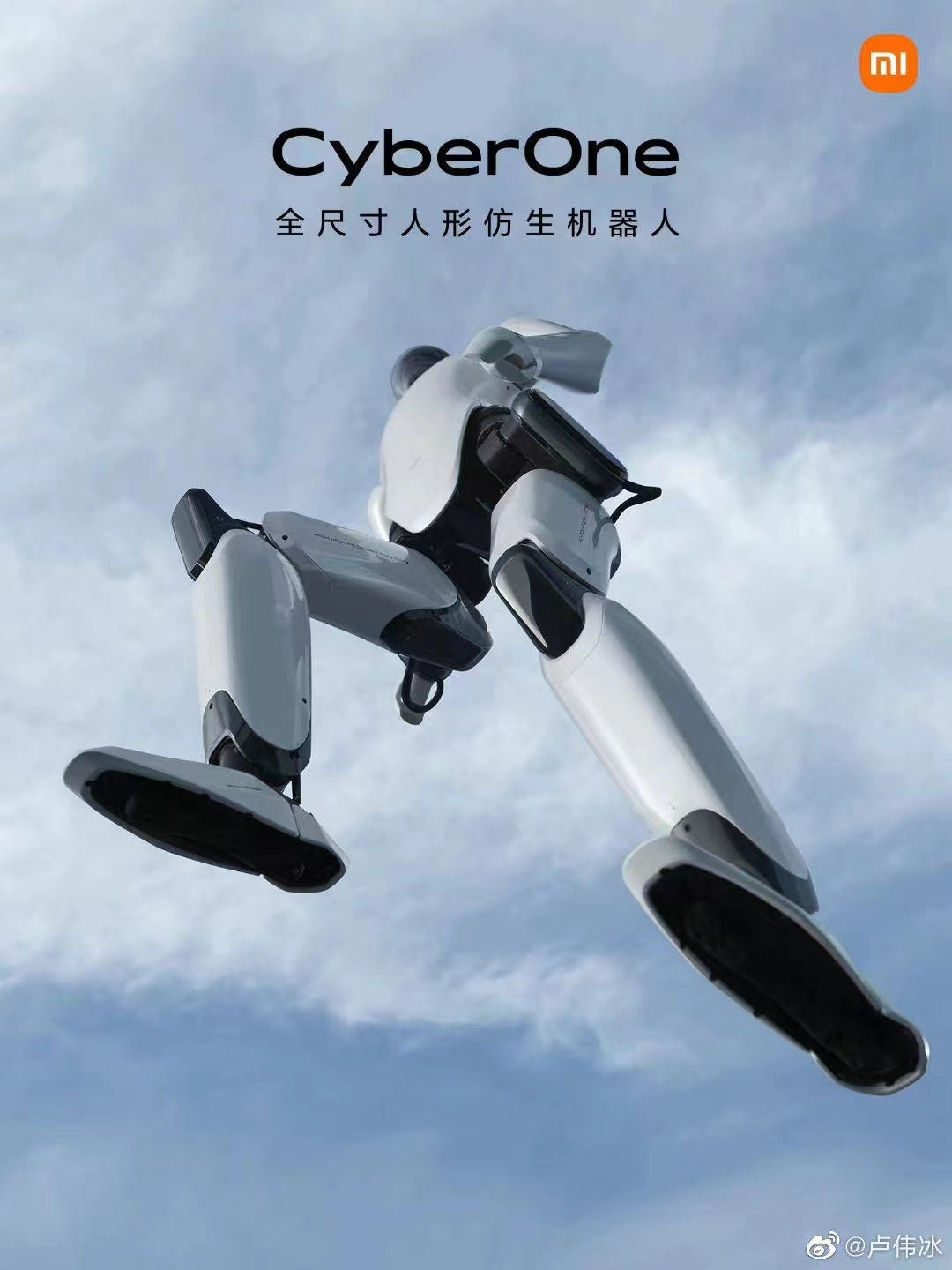

Image Source: Weibo "Lu Weibing"

The second reason is the reusability of experience and technology. Human behavioral logic can also be applied to humanoid robots. Humans can transfer their physiological structural changes and principles of human movement when walking to humanoid robots, reducing development thresholds while also lowering training costs.

The third reason is their ability to provide emotional value, which may sound mystical but is a point that cannot be overlooked. After all, the appearance of humanoid robots is similar to that of humans, making them more readily accepted by people.

Just like Doraemon, after spending extended periods with humans, many people forget that Doraemon is actually a childcare robot.

Image Source: 'Doraemon' Animation

The 'Three Hurdles' Faced by Humanoid Robots

The outlook for humanoid robots is promising, but that's in the future. At present, humanoid robots still need to confront numerous challenges.

The first hurdle is poor battery life, a common issue for electronic products, and robots are no exception. According to experts, the battery life of most humanoid robots currently stands within 2 hours.

To be honest, this battery life is somewhat disappointing, limiting their continuous working hours and application range. After all, humans expect robots to operate for extended periods under high loads. If they can only function for two hours, it's genuinely difficult to meet human expectations.

Image Source: pexels

To extend battery life, either the battery capacity needs to be increased or energy consumption needs to be reduced. The former has high requirements for battery materials, with the research goal being to discover materials with higher energy density, longer service life, and shorter charging times.

Today's mainstream lithium-ion batteries cannot meet the long-lasting battery life needs of robots in terms of energy density and service life. Without a substantial breakthrough in battery technology, the idea of increasing robot battery life by adding batteries is not very realistic.

Theoretically, solid-state batteries are an ideal research direction, but this will also require considerable manpower, material resources, and time for research.

Reducing energy consumption might be a feasible solution, as high intelligence also implies high energy consumption. Humanoid robots need to process numerous instructions in a very short period, naturally consuming more energy.

From the solutions provided by current manufacturers, reducing the weight of robot body materials and improving algorithms can enhance the battery life of humanoid robots.

Image Source: Xpeng Motors Official Website

The second hurdle is mechanical design flaws, which were evident in the world's first humanoid robot half marathon. Robots that previously moved smoothly in demonstration videos frequently fell over on the real racecourse.

Image Source: Leitech

Scenes such as falling immediately after starting and running out of control into barriers emerged successively. These were all caused by flaws in the robots' mechanical design.

Although the robots participating in the race had "steel bones and iron muscles", the motors inside their body joints would crash due to overheating, leading to issues like deformed movements and increased energy consumption, raising concerns about reliability.

Image Source: Leitech

The third hurdle is the difficulty of data collection and simulation. The training of humanoid robots requires a vast amount of data, but the cost of collecting this data, its quality, and storage costs are all substantial expenses.

If large models like Deepseek are later integrated, there will be even higher requirements for data processing and storage for the entire humanoid robot.

Currently, humanoid robots are touted as already working in factories, but in reality, they are only performing repetitive, low-tech tasks such as box carrying and screwing. They have not yet been able to execute more complex and advanced tasks, which is a limitation of current humanoid robot applications.

Image Source: Xpeng Motors Official Website

The Path to Commercialization is Particularly Bumpy

After any product is launched, it needs to confront the issue of commercialization. Humanoid robots are no exception. So, what is the commercialization prospect for humanoid robots?

The ideal is full, but the reality is bony. In the short term, humanoid robots are not a lucrative business - high R&D costs, long R&D cycles, and slow implementation all hinder the path to their commercialization.

According to media reports, currently, domestically produced humanoid robots are priced at over 600,000 yuan, a price that deters many consumers.

Among these, mass production before commercialization is considered the final challenge for humanoid robots. After all, no matter how impressive the demonstrations of humanoid robots are, if they cannot appear in front of consumers, it will be difficult to convince the public.

Especially after scenes like the robot marathon and robot games emerged, the outside world remains skeptical about the future prospects of humanoid robots.

Image Source: Leitech

Furthermore, the individual differences among humanoid robots also make users apprehensive. Reaching the stage of mass production proves that the quality and performance of the robots are basically stable and generally will not have major issues.

If the quality of mass-produced robots is inconsistent, buying a robot would be akin to buying a blind box, which is somewhat absurd.

How to dispel users' concerns and truly let humanoid robots 'enter' households is the core issue that needs to be addressed for their commercialization.

Summary

2025 marks the first year of mass production for humanoid robots, symbolizing their exit from laboratories and their attempt to integrate into human society. After experiencing robot marathons and games, the robot industry has also witnessed new reflections. Cost reduction, efficiency enhancement, and commercialization are all challenges that current robot manufacturers need to face. Perhaps the entire industry will also undergo a significant reshuffle.

The marathon for humanoid robots has ended, but the marathon for their commercialization has just begun.

Source: Leitech

Images in this article are from: 123RF Stock Photo Library Source: Leitech