Apple Confronts Unprecedented Challenge: Navigating 104% Tariffs and Industrial Chain Complexity

![]() 04/10 2025

04/10 2025

![]() 400

400

When it comes to the recent U.S. tariffs, Apple and its extensive supply chain undoubtedly bear the brunt of the impact.

Trump's recent actions have been particularly aggressive, with tariffs on China rising to a staggering 20% + 34% + 50%, amounting to a maximum rate of 104%.

For Apple, which manufactures 98% of its smartphones and 85% of its wearable devices in China, these tariffs are unbearable, and relocating industrial chains is far from a simple task. The problem seems intractable.

I. Tariffs Push Past Cost Thresholds

Taking the Apple iPhone as an example, its imports are subject to a cumulative tariff rate of 104%—a basic tariff of 20%, a retaliatory tariff of 34%, and a special tariff of 50%. This means that a $1,000 watch would incur a tariff cost of $1,042, exceeding its selling price.

Even if we exclude extreme cases and focus solely on the hardware cost of the iPhone, each phone would incur an additional tariff of approximately $600, directly eroding its 60% gross margin.

In fiscal year 2025, Apple's gross margin was 42%, and its net profit margin was roughly 24%. How can it sustain such a financial burden?

II. Industrial Migration Faces Practical Hurdles

Perhaps this is precisely what Trump intends—to force the manufacture of these products in the U.S. under high tariffs, revitalizing American manufacturing. However, the U.S.'s expected "restructuring of industrial chains" encounters significant engineering-level challenges. An iPhone comprises over 800 precision components, with more than 70% undergoing deep processing in mainland China.

By using tariffs as a "deportation order," the U.S. overlooks the robust reality of the Chinese supply chain. Even if Apple were willing to bear the migration costs, how many years would it take to establish such a supply chain in the U.S.? It might not even be completed by the end of Trump's term, and Apple does not have the luxury of time.

III. The Fortified Ecosystem of Made in China and Its Supply Chain

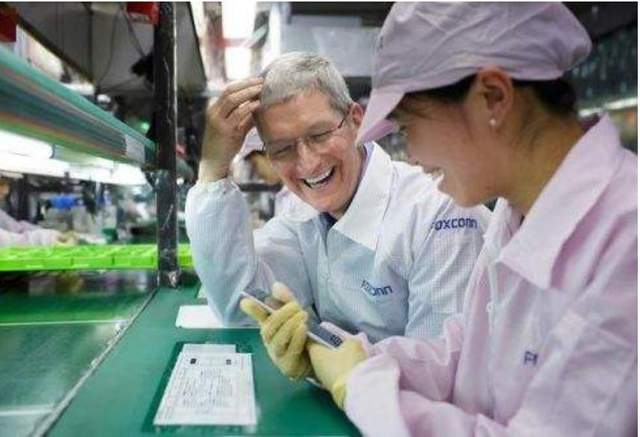

The "three-hour industrial circle" of China's Foxconn supply chain vividly demonstrates its irreplaceability. Within a 50-kilometer radius centered on the park, there are 47 types of core component suppliers, including camera modules, linear motors, and OLED screens, capable of responding to urgent orders within two hours. This consumer electronics ecosystem, built by 12,000 enterprises, requires the U.S.'s railway infrastructure and Mexico's mold standard system reconstruction—migration costs that are unimaginable. Perhaps even years of Apple's profits would not suffice to cover them.

Realistic Dilemmas and Potential Solutions

Under the immense pressure of tariffs, Apple finds itself in its toughest predicament, with no clear path to resolution.

As an analyst noted, "The deep integration of the Chinese supply chain is the outcome of natural selection over the past three decades." As evidenced by a Boston Consulting Group report, Chinese manufacturing maintains a generational advantage of over a decade in the consumer electronics field. This is a reality that tariff barriers cannot erase. How many years does Trump have left in office? Can he bridge this decade-long generational gap?