RTE Ready-to-Eat Meat Products Witness Major Innovation in Sterilization Technology! Quintus HPP Ultra-High Pressure Technology Paves the Way for Safer and Healthier Food Industry Upgrades

![]() 02/24 2025

02/24 2025

![]() 543

543

In the fast-paced modern lifestyle, ready-to-eat meat products (RTE) have garnered significant consumer favor due to their high protein content and convenience. Market projections indicate a continued expansion of this market at a compound annual growth rate of 4.8% in the coming years, with North America, China, and Brazil emerging as the most prosperous regions. However, amidst this rapid growth, food safety concerns have become increasingly pronounced, posing a bottleneck for industry advancement. In this context, Quintus HPP ultra-high pressure processing technology stands out with its distinct advantages. This technology inactivates microorganisms through high pressure, without the need for heating or chemical additives, thereby preserving the original taste and nutritional value of food. This ensures the safety of RTE meat products and meets consumer demands for minimally processed, clean-label, and healthy food options.

Safety Challenges for Ready-to-Eat Meat Products

Foodborne pathogenic bacteria such as Salmonella, Listeria, and Escherichia coli O157 pose a serious threat to the healthy development of the RTE meat products industry. Among them, Listeria monocytogenes is particularly problematic as it can survive and reproduce in extreme environments, with cold storage, warehouses, and processing equipment surfaces serving as potential hiding spots. The disease caused by this bacterium, listeriosis, has a high fatality rate among the elderly, pregnant women, and immunocompromised individuals. In 2017, the European Union reported 270 deaths attributed to Listeria, a shocking statistic.

Furthermore, frequent product recalls due to contamination by pathogens like Listeria severely damage brand images and significantly impact economic benefits. Food safety issues have emerged as a critical factor hindering the growth of the RTE meat products industry. Following food safety incidents, product recalls can lead to tarnished brand images, declining sales, and potential legal proceedings and financial crises for enterprises. Studies reveal that food safety issues can cause a significant drop in a company's share price within two months, with recovery taking up to a year, resulting in far-reaching and lasting negative impacts.

Solution – HPP Ultra-High Pressure Processing

In the face of food safety challenges, it is imperative for RTE meat product manufacturers to adopt efficient safety measures. In this regard, Quintus HPP ultra-high pressure processing technology shines with its unique benefits. HPP technology utilizes high pressure to inactivate bacteria, viruses, molds, and yeasts without heating or adding chemical additives, thus preserving the original flavor and nutritional content of food. This non-thermal processing method not only ensures the safety of RTE meat products but also aligns with consumer preferences for minimally processed, clean-label, and healthy food options.

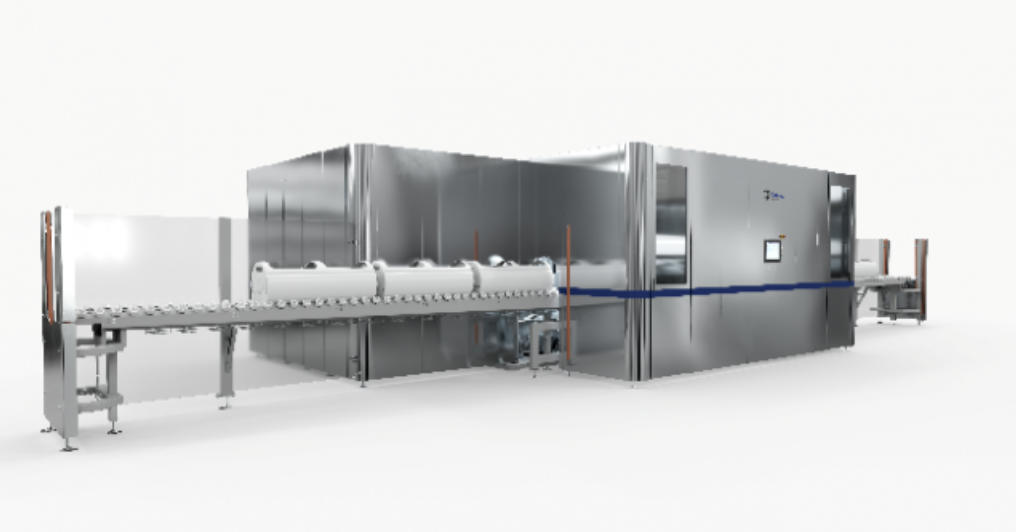

QIF 600L

As consumers increasingly seek minimally processed, clean-label, and healthy food, the application of HPP technology in the global RTE meat products industry continues to expand. Global manufacturers are actively incorporating HPP processing technology to diversify their product lines and cater to evolving consumer tastes. As an end-of-production process, HPP is applied post-final packaging and is compatible with various soft packaging options, tailored to product characteristics. Once the packaged product is placed in a pressure vessel and filled with water, the pressure permeates evenly, disrupting the cell membranes and biochemical pathways of microorganisms, achieving efficient sterilization and ensuring product safety.

Beyond ensuring food safety and extending shelf life, HPP technology offers numerous additional advantages to the RTE meat products industry. For instance, during slicing operations, the risk of contamination by pathogens like Listeria significantly increases. However, there are limited methods for further sterilization of sliced RTE meat products. As a post-final packaging process, HPP technology can inactivate various pathogens, including those remaining or newly introduced post-processing, thereby ensuring food safety. Additionally, HPP technology enhances curing effects, tenderizes raw proteins, reduces moisture loss, and increases yield. These benefits have contributed to the widespread adoption of HPP technology in the RTE meat products industry.

Scientific Validation & Quality Assurance

As an innovative force in food safety, HPP technology has been scientifically validated to effectively inactivate foodborne pathogenic bacteria. It significantly reduces the number of various pathogens, including Salmonella, Listeria, and Escherichia coli O157, by more than 5 logs, and can even completely eliminate inoculated pathogens. Simultaneously, HPP technology maintains the quality and nutrition of RTE meat products and other foods while reducing the number of spoilage microorganisms, earning widespread recognition for post-sterilization control of pathogens like Listeria in RTE meat products.

Taking pre-packaged grilled beef seasoned with barbecue sauce as an example, the microbial count remained low after 126 days of storage at 4°C, with no adverse sensory signs (such as gas production or off-odors) detected in HPP-treated samples. In contrast, control group samples without HPP treatment exhibited obvious signs of spoilage during storage. This result clearly demonstrates that HPP technology can significantly extend product shelf life and maintain microbiological stability.

Quintus, Supporting Food Safety

With consumers' escalating demands for health, taste, and convenience, the application of Quintus HPP technology in the global RTE meat products industry continues to grow. Global manufacturers are actively incorporating HPP processing technology to diversify their product offerings and meet evolving consumer preferences. Meanwhile, research conducted by universities and regulatory agencies further substantiates the significant effect of HPP in eliminating foodborne pathogenic bacteria, reinforcing its crucial role in ensuring food safety.

Looking ahead, HPP technology will continue to spearhead the RTE meat products industry towards safer and healthier development. As an industry technology leader, Quintus is driving the RTE meat products industry towards a new future with its advanced HPP technology and extensive application experience. Through continuous innovation and technology optimization, Quintus is committed to providing global consumers with safer, healthier, and more delicious RTE meat product options.

To learn more about Quintus food processing, visit the Quintus official website or follow the official WeChat public account 'Quintus Technologies'.