Revolutionizing Medical Device Manufacturing: Quintus Hot Isostatic Pressing Overcomes α-Brittle Layer and Discoloration Challenges for Paragon Medical

![]() 02/24 2025

02/24 2025

![]() 375

375

In the realm of medical product manufacturing, precision and reliability stand as paramount requirements. However, during the additive manufacturing (AM) process, particularly when fabricating titanium alloy implants with intricate trabecular bone structures, microscopic defects such as the formation of α-brittle layers frequently arise. These brittle layers can develop during heat treatment processes, including Hot Isostatic Pressing (HIP), potentially damaging the implant's microstructure and performance, thereby jeopardizing patient safety. Quintus, with its cutting-edge HIP technology and innovative solutions, has played a pivotal role in supporting Paragon Medical, helping it to navigate industry challenges and resolve issues related to α-brittle layers and discoloration.

Paragon Medical's HIP Technology Exploration and Challenges

Paragon Medical, a leading provider of precision engineering medical product solutions, specializes in the design, development, and manufacture of surgical instruments, implantable products, and other medical components. Serving a diverse range of fields including orthopedics, cardiovascular, and life sciences, Paragon has extensive experience in the additive manufacturing of medical products, from product development and commercialization to mass production. The company is renowned for its on-time delivery and efficient operations, earning widespread industry acclaim.

Quintus HIP Equipment at Paragon Medical

Traditional solutions, such as wrapping parts in stainless steel bags or foil prior to HIP processing, or applying mechanical or chemical treatments post-HIP, are not only time-consuming and labor-intensive but also costly. Moreover, their effectiveness in addressing complex structures is often limited.

To establish an end-to-end additive manufacturing medical product solution, Paragon Medical decided to incorporate HIP technology into its internal production processes. However, as a newcomer to HIP, the company faced two significant challenges:

- High technical threshold for HIP technology: Mastering equipment operation and process optimization as a HIP newcomer.

- α-brittle layer challenge: Mitigating the formation of brittle oxide layers during titanium alloy implant heat treatment, which can lead to performance degradation and non-compliance with ASTM standards.

Quintus® Care: From Technical Empowerment to Comprehensive Support

To fully harness the potential of its internal HIP process, Paragon Medical chose to deepen its collaboration with Quintus by enrolling in the Quintus Care program. Through this framework, Paragon Medical gains access to Quintus's application support and the Quintus Application Center, offering cutting-edge knowledge, case studies, and the latest technology trends in additive manufacturing (AM). Additionally, Quintus provides professional and in-depth technical training, regular equipment inspection services, and priority technical support from Quintus experts.

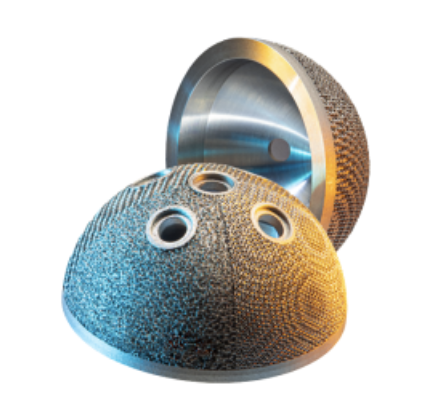

Paragon Medical - AM Spinal Cage

A senior quality engineer from Paragon Medical's additive manufacturing department commented, "The professional support from the Quintus team has enabled us to achieve significant technological advancements in a short period, dramatically improving the stability of our HIP process." With deepening cooperation, Paragon Medical has notably enhanced its technical capabilities in HIP equipment operation and maintenance, maximizing the potential of HIP technology. This transformation has not only bolstered the team's professional skills but also ensured the efficient operation and long-term reliability of the equipment.

Quintus Purus®: Tackling α-Brittle Layer and Discoloration Issues

In pursuit of superior medical product solutions, Paragon Medical spearheaded the introduction of Quintus Purus, an innovative toolkit designed to ensure a pristine HIP process. This toolkit significantly reduces oxidation and effectively eliminates issues such as the α-brittle layer formed during titanium alloy implant heat treatment. Following a comprehensive process upgrade and rigorous validation, Paragon Medical continuously monitored the formation of the α-brittle layer and product appearance consistency, achieving results that perfectly met expectations.

Paragon Medical - AM Acetabular Cup

Through its close collaboration with Quintus, Paragon Medical has not only further optimized its integrated additive manufacturing solutions for medical equipment but also significantly improved overall production efficiency and product quality. The implementation of the Quintus Care program has profoundly enhanced Paragon Medical's understanding and mastery of HIP technology. Coupled with the Quintus Purus upgrade solution, these innovative initiatives and close partnerships underscore the exceptional value and far-reaching impact of both parties in driving technological advancements in the medical device industry.

Why Choose Quintus

As a global leader in high-pressure technology, Quintus has delivered over 1,900 systems, serving high-precision fields such as medical and aerospace:

- End-to-end support: Provides full lifecycle services from equipment design, process development to continuous operation.

- Innovative technology reserves: Patented toolkits (such as Purus®) address industry pain points and enhance process efficiency.

- Global localized service: Teams in Sweden, the US, and China collaborate to ensure rapid response.

About Paragon Medical

As a strategic partner in medical device manufacturing, Paragon offers end-to-end supply chain solutions, encompassing concept design, product development, validation testing, mass production assembly, and continuous strategic demand planning. With multiple campuses globally and over 1.2 million square feet of operating space, Paragon boasts rapid prototyping innovation centers, automated engineering solutions facilities, and world-class biotechnical laboratories, dedicated to providing innovative solutions and high-quality products to customers in the medical industry.

For more information on Quintus hot isostatic pressing, search for Quintus and visit the official website or follow the official WeChat public account "Quintus Technologies".