["AI Intelligence Refining, Industrial Pioneering" Issue 2 | GCI × DeepSeek: Revolutionizing AI Large Model Operations Management

![]() 02/28 2025

02/28 2025

![]() 420

420

After setting annual business strategic goals and breaking them down across various domains, CEOs often grapple with several critical questions: How can we predict the achievement of these goals? Are there risks of non-attainment? Can these risks be mitigated in advance? Similarly, once each domain receives its strategic goals, CFOs, CTOs, CHOs, CSOs, COOs, and CMOs, among others, focus on these same issues as they align workloads and assign tasks to individual business units.

When business goals are cascaded down to specific production lines, factory workshop directors face unique challenges. In the process of dissecting production demands and allocating indicators, they often encounter bottlenecks such as inflexible production planning, delayed production data feedback, inefficient cross-departmental resource coordination, mismatches between personnel skills and tasks, and complex quality control and traceability processes. These issues compromise the validity of frontline production data.

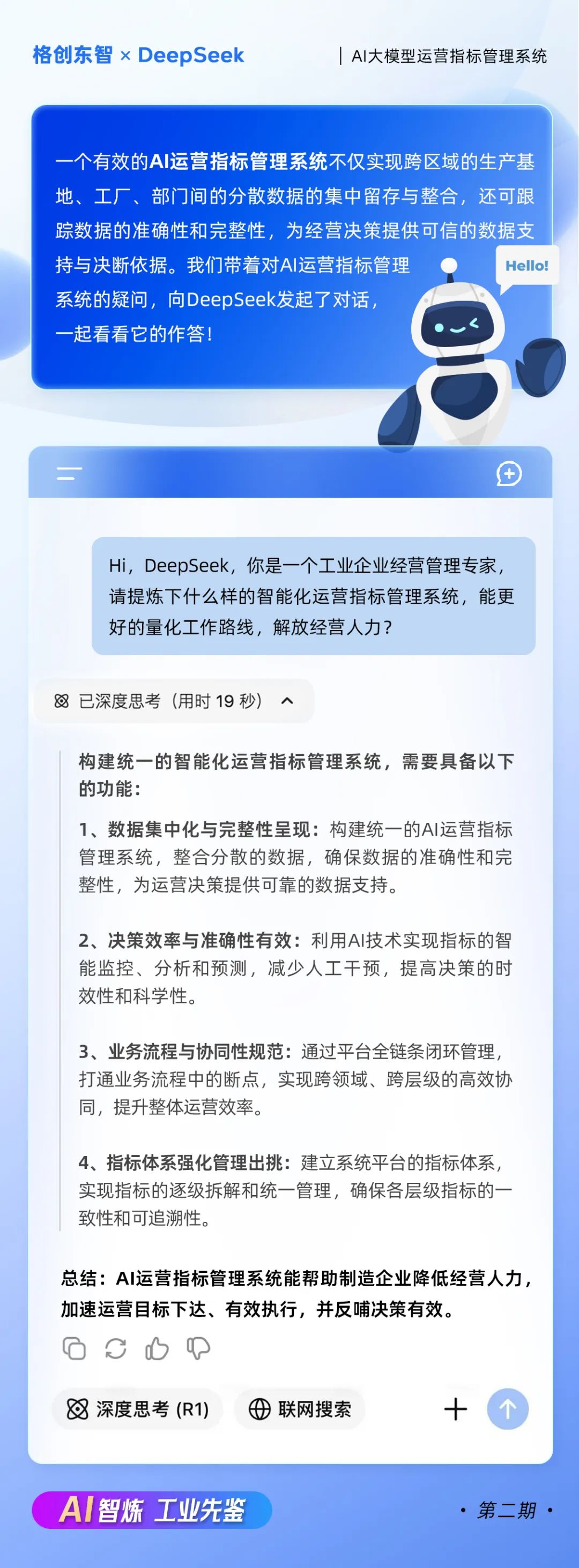

Discrepancies in frontline production data can trigger a domino effect, directly impacting the group's operational metrics management and control. Issues like poor data monitoring timeliness, inadequate decision-making foundations, execution tracking difficulties, business process disruptions, and cross-level collaboration barriers emerge, leading to operational inefficiencies and business losses. Consequently, enterprises strive to establish a unified AI operation metrics management system to introduce precision in production operations.

GCI, a pioneering enterprise in industrial intelligence solutions, has embedded AI capabilities into its product and service offerings since its inception six years ago. It aims to exclusively support the "digital blue sky" of advanced manufacturing with highly effective services. GCI believes that these challenges can be addressed through a shift in perspective. The company's self-developed AI large model operation metrics management system is designed to aid manufacturing enterprises in transitioning from digital to AI-driven intelligent operations. The system quantifies operational goals from the strategic to the execution level across various business domains and departments. Through a unified AI large model operation metrics management system, customers can achieve operational targets, monitor process data indicators, conduct real-time management and control, and implement pre-interventions to ensure the achievement of ultimate strategic goals. Notably, the system now integrates large models with traditional AI algorithms, supporting innovative features such as AI-powered indicator creation, definition, and query, intelligent analysis, and automated report generation. This aims to reduce labor costs, identify business improvement opportunities, and support customers' shift from leadership- and function-driven to data-driven operations.

To date, GCI's AI large model operation metrics management system has established "operation command centers" for hundreds of pan-semiconductor factories, demonstrating significant advantages in addressing various operational challenges:

As an industrial intelligence solution provider with deep insights into advanced manufacturing, particularly in the semiconductor industry, GCI leverages over 40 years of industry expertise from TCL Group. It has constructed a full-stack, independently controllable system and developed an AI large model platform. This platform deeply integrates advanced intelligent AI tools into multiple business scenarios, including manufacturing execution, equipment automation, quality management, energy and carbon management, logistics automation, and digital supply chains. GCI maintains a leading position in technological prowess, industry recognition, and customer satisfaction. Recently, GCI integrated with DeepSeek, significantly enhancing customers' digital experience in production and operations. The company relentlessly promotes AI empowerment and upgrading to improve human efficiency, reduce costs, enhance decision-making quality, optimize business processes, and bolster corporate competitiveness, thereby unlocking business value.

In 2025, GCI will continue to integrate the latest advancements in domestic large models, investing nearly 100 million yuan. The company will focus on AI general platform service tools and AI algorithm technological innovation, deepening the integration of "AI + manufacturing" in the pan-semiconductor field. This will empower the high-quality growth of advanced manufacturing.